| The gold salt consumption of electroplating gold wire mainly includes the consumption of the gold layer of the printed circuit board pattern and the consumption of the bath liquid. If the gold plating layer is too thick or the amount of bath solution is too large, the gold salt will be wasted and the cost of ineffective gold salt will be generated.

Gold plating thickness control

Currently, the thickness of the gold-plated layer is mainly controlled based on the requirements of the production instructions and remarks, and there is almost no control over the upper limit of the gold-plated layer thickness. In view of this status quo, internal gold plating thickness control standards can be formulated. Relevant departments signed an internal contact form for the control of the thickness of the gold-plated layer to effectively control the upper limit of the thickness of the gold-plated layer within the scope of equipment and technical capabilities without affecting the quality of the production board. According to the “Gold-plated Layer Thickness Control Refined Management Internal Contact Sheet” of the Guangzhou plant, combined with the characteristics of the products in the Zhuhai plant, the content of the internal contact list was modified and improved, and re-signed and executed.

Process parameter control

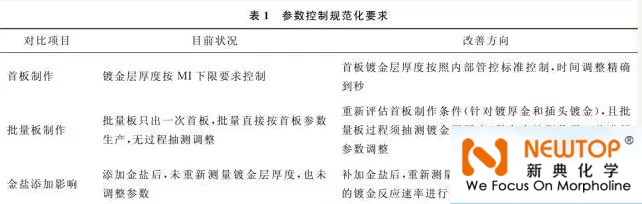

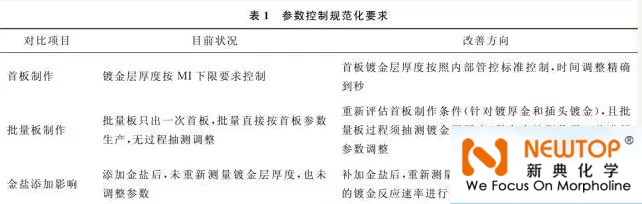

1. Potion stability control Potion stability is a decisive factor affecting the rate of gold plating reaction. As the main consumption component of the gold plating reaction, the concentration of gold ions will also fluctuate with production consumption. The fluctuation of the gold salt concentration will in turn lead to the fluctuation of the gold plating reaction rate. Therefore, in order to ensure the stability of the gold plating reaction rate, the concentration of the gold salt in the gold bath must be maintained at a relatively stable level. Under the premise of drug stability, the setting and adjustment of the gold plating parameters will be more accurate, and the thickness of the gold plating layer will be more stable. In order to maintain the stability of the gold salt concentration in the gold tank, the following two points must be paid attention to: (1) Maintain the accuracy and completeness of the production record; (2) Maintain the timeliness of the gold salt replenishment, and follow the “small amount of times” in principle. 2. The standardization of parameter-controlled interleaving production of bulk plates and batch plates requires the control of the production of the first plate, the thickness of the gold plating layer of the batch plate and the gold salt addition process. The specific improvement requirements are shown in Table 1.

3. Monitoring measures for the thickness of the gold-plated layer In order to ensure the monitoring effect, the following monitoring measures are now formulated. (1) Formulate the “Gold Salt Cost Saving Project Monitoring Table” in view of the content of the gold plating layer thickness control, formulate the “Gold Salt Cost Saving Project Monitoring Table” to control the completeness of production records, the timeliness of gold salt addition, and the thickness control of the first gold plating layer , Inspection of items such as the thickness control of the gold plating layer of the batches and the adjustment of the parameters after the addition of gold salt, and the analysis and improvement of non-conforming items. (2) The ERP gold-plated layer thickness data is improved. The gold salt consumption data exported from the current ERP system is partially incorrect and incomplete. The software requirement form must be submitted to the information center to complete the module to ensure that the gold salt consumption data is accurate and complete. (3) Statistical analysis of gold-plated layer thickness data Export ERP gold-plated layer thickness data records every week, perform statistics according to line type and gold-plated layer thickness requirements, analyze the implementation and stability of the gold-plated layer thickness control of each line, and perform abnormal points Analysis and improvement. Optimizing the uniformity of gold plating If the uniformity of gold plating on a thick gold-plated wire is low, it will seriously affect the control of the thickness of the gold-plated layer during the production process. In the production process, in order to meet the customer’s minimum gold plating thickness requirements, the gold plating layer is often thicker, causing serious waste of gold salt. In order to optimize the uniformity of the thick gold plating bath, the improvement can be started by changing the setting method and position of the anode titanium mesh in the bath, and the best solution can be found through technical testing. At the same time, in the gold plating process, for relatively small production boards, anode baffles can be used for production, which can also significantly improve the uniformity of gold plating. Reducing the amount of tank liquid carried out If there is a big deviation in the grasp of time, insufficient dripping time will cause the amount of tank liquid carried out to be too large, and too long dripping time will cause a reduction in production efficiency and a waste of capacity. At the same time, if a vibrating device is added, the bath liquid attached to the plate surface can drip faster under the action of external force, which can effectively reduce the amount of bath liquid carried out, shorten the dripping time, and increase efficiency. At the same time, an auxiliary bracket is added to the drip bracket of the gold-plated tank, so that the gold-plated fixture forms an angle of 45° with the vertical direction, which can speed up the dripping of the plate surface tank liquid. Because when the production board is hung normally, the whole edge of the lower end of the board becomes the convergence point of the tank liquid on the board surface. When tilted and hung, the liquid converging point is at the corner of the plate, which can accelerate the liquid converging and dropping on the plate surface. 3. Monitoring measures for the thickness of the gold-plated layer In order to ensure the monitoring effect, the following monitoring measures are now formulated. (1) Formulate the “Gold Salt Cost Saving Project Monitoring Table” in view of the content of the gold plating layer thickness control, formulate the “Gold Salt Cost Saving Project Monitoring Table” to control the completeness of production records, the timeliness of gold salt addition, and the thickness control of the first gold plating layer , Inspection of items such as the thickness control of the gold plating layer of the batches and the adjustment of the parameters after the addition of gold salt, and the analysis and improvement of non-conforming items. (2) The ERP gold-plated layer thickness data is improved. The gold salt consumption data exported from the current ERP system is partially incorrect and incomplete. The software requirement form must be submitted to the information center to complete the module to ensure that the gold salt consumption data is accurate and complete. (3) Statistical analysis of gold-plated layer thickness data Export ERP gold-plated layer thickness data records every week, perform statistics according to line type and gold-plated layer thickness requirements, analyze the implementation and stability of the gold-plated layer thickness control of each line, and perform abnormal points Analysis and improvement. Optimizing the uniformity of gold plating If the uniformity of gold plating on a thick gold-plated wire is low, it will seriously affect the control of the thickness of the gold-plated layer during the production process. In the production process, in order to meet the customer’s minimum gold plating thickness requirements, the gold plating layer is often thicker, causing serious waste of gold salt. In order to optimize the uniformity of the thick gold plating bath, the improvement can be started by changing the setting method and position of the anode titanium mesh in the bath, and the best solution can be found through technical testing. At the same time, in the gold plating process, for relatively small production boards, anode baffles can be used for production, which can also significantly improve the uniformity of gold plating. Reducing the amount of tank liquid carried out If there is a big deviation in the grasp of time, insufficient dripping time will cause the amount of tank liquid carried out to be too large, and too long dripping time will cause a reduction in production efficiency and a waste of capacity. At the same time, if a vibrating device is added, the bath liquid attached to the plate surface can drip faster under the action of external force, which can effectively reduce the amount of bath liquid carried out, shorten the dripping time, and increase efficiency. At the same time, an auxiliary bracket is added to the drip bracket of the gold-plated tank, so that the gold-plated fixture forms an angle of 45° with the vertical direction, which can speed up the dripping of the plate surface tank liquid. Because when the production board is hung normally, the whole edge of the lower end of the board becomes the convergence point of the tank liquid on the board surface. When tilted and hung, the liquid converging point is at the corner of the plate, which can accelerate the liquid converging and dropping on the plate surface.

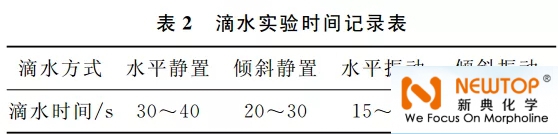

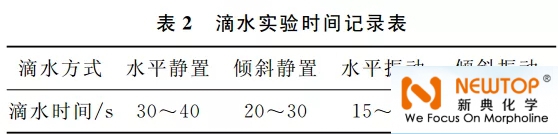

Table 2 shows the statistics of the dripping time of the four dripping modes of horizontal standing, inclined standing, horizontal vibration and inclined vibration (with no obvious droplet dripping as the end point of dripping, manual simulation of vibration). It can be seen from the above verification data: Setting the dripping mode to oblique vibration can ensure the dripping effect in a short dripping time. Table 2 shows the statistics of the dripping time of the four dripping modes of horizontal standing, inclined standing, horizontal vibration and inclined vibration (with no obvious droplet dripping as the end point of dripping, manual simulation of vibration). It can be seen from the above verification data: Setting the dripping mode to oblique vibration can ensure the dripping effect in a short dripping time. |