4100 esterification catalyst

Overview:

Chinese name: Monobutyl tin oxide

Alias: plasticizer, drier, monobutyl tin oxide, 4100, esterification catalyst, imported 4100, silicone curing catalyst, CAS#2273- 43-0, butyl stannic acid; butyl tin oxyhydroxide; monobutyl tin oxide; monobutyl tin hydroxide; butyl stannic oxyhydroxide; butyl enoic acid; n-butyl tin oxide hydroxide; butyl stannic acid

English name: 4100, Butyltin oxide, BUTYLENESTANNONIC ACID;BUTYLTINHYDROXIDE-OXIDE;BUTYLTIN(IV) HYDROXIDE OXIDE;BUTYLSTANNOIC ACID;N-BUTYLSTANNOIC ACID;N-BUTYLTIN HYDROXIDE OXIDE;N-BUTYLTIN SESQUIOXIDE;1-butanestannonicacid

| CAS 2273-43-0 | Monobutyl tin oxide | 4100 esterification catalyst | Silicone curing catalyst | Butyltin oxide |

Physical and chemical performance:

Monobutyl tin oxide 4100

The 4100 series is a multi-purpose product of white solid powder in barrels. As an esterification catalyst, it has thermal stability and hydrolysis resistance. The product is neutral and has no It is corrosive and does not need to be separated after the reaction is completed. As a polyester catalyst, it can form a stable decomposition system in the coating. At the same time, it is also an intermediate raw material for the synthesis of polyvinyl chloride stabilizers and organic silicon curing catalysts. -4100-Monobutyl tin oxide: Sn% ≥ 56 CHF-4101, dibutyl tin oxide: Sn% ≥ 48.2.

CAS 2273-43-0 Monobutyltin oxide 4100 esterification catalyst Silicone curing catalyst Butyltin oxide

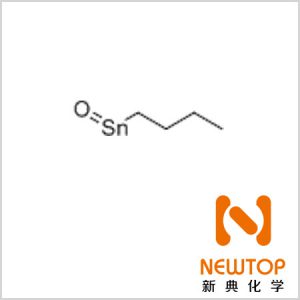

Molecular formula: BuSnOOH

Molecular weight: 208.81

CAS#2273-43-0

EC#218-880-1

Molecular formula C4H10O2SN

Properties: White powder, insoluble in water and general solvents, but soluble in strong alkali.

Specifications: Tin content: 57.5±0.5%

Salt content: ≤0.05%

Iron content: ≤0.003%

Loss on drying: ≤1.0%

Melting point: directly decomposes at high temperature without dissolving.

4100 catalyst is a solid, hydrolytically stable catalyst.

4100 catalyst mainly catalyzes esterification and polycondensation reactions at 210℃~240℃.

During the reaction process, the 4100 catalyst begins to dissolve in the carboxylic acid at 80°C and merge with the final product without affecting the quality of the product.

4100 catalyst can be used at temperatures up to 250°C.

4100 catalyst is neutral and non-corrosive.

Pros:

Compared with the reaction system without catalyst, 4100 catalyst can greatly shorten the reaction period of esterification.

Since only a lower reaction temperature is required, 4100 catalyst can reduce energy consumption.

4100 catalyst can reduce side reactions to *, such as: dehydration and oxidative degradation of polyols (especially secondary alcohols)

4100 catalyst can be mixed with other reactants in advance, no other special treatment is required, except to avoid moisture.

4100 catalyst does not need to be neutralized or filtered at the end of the reaction.

Purpose:

4100 catalyst can be used in the synthesis of saturated polyester powder coatings and coil coatings.

4100 catalyst can be used in the production of unsaturated polyester in gel coatings, sheet molding compounds and casting applications.

4100 catalyst can be used in the production of polymeric plasticizers.

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse.

Packaging:

Packing: 25Kg cardboard drum.