Dimethylbenzylamine CAS 103-83-3 N-dimthylbenzylamine

Dimethylbenzylamine CAS 103-83-3 N-dimthylbenzylamine

Dimethylbenzylamine CAS 103-83-3 N-dimthylbenzylamine

PU Catalyst: BDMA (benzyldimethylamine) CAS:103-83-3

Over view:

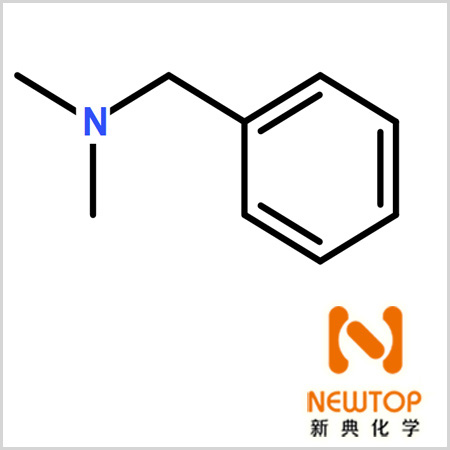

Common Name: Benzyl Dimethyl Amine

Other Chemical Names: N,N-Dimethylbenzylamine, Benzenemethamine, N,N-dimethyl-;Benzenemethanamine,N,N-dimethyl-;Benzylamine,

Physical and chemical properties:

Appearance |

Form: transprant light yellow liquid |

Odour |

no data available |

PH |

10 at 10 g/l at 20 °C |

Melting point/freezing point |

Melting point/range: -75 °C – lit. |

Initial boiling point and boiling range |

181 – 184 °C at 1.020 hPa – lit. |

Flash point |

53 °C – closed cup |

Evaporation rate |

no data available |

Flammability (solid, gas) |

Upper explosion limit: 6,3 %(V) |

Upper/lower flammabilityor explosive limits |

Lower explosion limit: 0,9 %(V) |

Relative density |

0,9 g/cm3 at 25 °C |

Water solubility |

soluble |

Partition coefficient: noctanol/water |

log Pow: 1,87 |

Molar formular |

C9H13N |

Molar mass |

135.21 |